30 years of slope stabilisation Fortrac Systems

Project information

Construction project

Widening of the M25 motorwayCustomer

Tarmac. Mowlem & LaingsConstruction

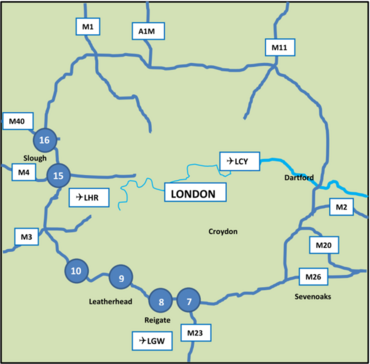

Comtec UK Ltd.Location

London , GBPlaning

Comtec UK Ltd.Construction time

June 1993 to October 1996Products used

Project details

Project description

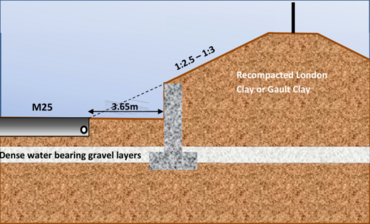

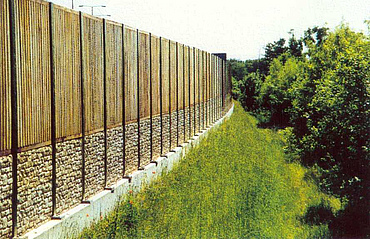

The geological composition of the terrain within the area of the widening section varies greatly and consists of chalk outcrops, terrace gravel and larger areas of highly plastic clay. In order to realize the planned widening of the carriageway, it was necessary to remove 4m of the flat embankment structures originally made of compacted clay. The embankments with a gradient of 1:3 were generally 4 to 5m high and served as a foundation base for noise barriers. In some areas, the embankments were built on water-bearing gravel, which was around 2 to 3m below the existing road level. The conforming solution for the retaining walls on the scheme consisted of RC cantilever walls. The low shear strengths of the clays meant overall stability gave the 2-3m high walls the 3m deep foundations necessary to achieve the required Lump Factor of Safety of 1.5. Prior to the publication of Eurocodes and the adoption of partial factors and limit state design, lump factor design was the norm in the UK and whilst structural solutions required a lump factor of 1.5 and a lengthy approval and checking process, geotechnical solutions which included Steep RSS up to 70° could be submitted with a simpler Geotechnical Certification. This meant quicker approval requiring a lower safety factor of 1.3 for global stability which in this case enabled the embedment depth of the steep slopes to be reduced to 1m ensuring the water bearing gravels were not encountered. On junctions 15-16 there was a reluctance to commit entirely to the RSS solution so the southbound slopes begun construction of the conforming RCC walls and the northbound carriageway was submitted for certification of the alternative.

Solution

Die geologische Beschaffenheit des Geländes im Bereich des Ausbauabschnitts variiert stark und besteht aus Kreideaufschlüssen, Terrassenschotter sowie größeren Bereichen mit hochplastischem Ton. Um die geplante Verbreiterung der Fahrbahn zu realisieren, war es notwendig vier Meter der ursprünglich aus verdichtetem Ton hergestellten flachen Dammstrukturen abzutragen. Die Dämme mit einer Neigung von 1:3 waren in der Regel vier bis fünf Meter hoch und dienten zudem als Gründungsboden für Lärmschutzwände. In einigen Bereichen lagen die errichteten Dämme auf wasserführendem Kies, welcher sich etwa zwei bis drei Meter unter dem bestehenden Fahrbahnniveau befand. Die Lösung für die Stützmauern des Projekts bestand aus freitragenden Wänden. Aufgrund der geringen Scherfestigkeit des Tons konnte die Gesamtstabilität durch 2-3 m hohe Wände mit 3 m tiefen Fundamenten erreicht werden. Da es sich um eine geogitterbewehrte Böschung (KBE) mit einer Böschungsneigung von bis zu 70° handelte, konnte der Vorschlag mit einem geotechnischen Zertifikat eingereicht werden, was die Genehmigung beschleunigte. Darüber hinaus wurde für KBE ein Sicherheitsfaktor (FS) von 1,3 für die Gesamtstabilität gefordert, während für Betonwände ein FS von 1,5 nachgewiesen werden musste. Ferner konnte die Einbindungs- bzw. Gründungstiefe der KBE auf 1 m reduziert werden, um ein Auftreffen auf die wasserführende Kiesschicht zu vermeiden. Daher wurden Teile der Kreuzung 15-16 mit der alternativen KBE-Lösung gebaut.

Advantages

In the area of junction 15-16, the north-side GRS was completed in just ten weeks, while the construction of the reinforced concrete walls took a total of seven months due to the necessary temporary work and drainage measures as well as the removal of the clay and the delivery of granular filling material. The higher speed, the elimination of temporary works and the delivery of the filling material increased safety on the construction site and also reduced the restrictions and risks for the public, as the necessary traffic controls and restrictions were significantly shorter. The direct comparison showed cost savings of 70% and a four times faster construction time, as well as a reduction in the CO2 footprint. Looking at the last 30 years of the 60-year lifespan, the slopes are virtually unchanged compared to their new condition. The only problem so far has been the initial difficulties with the vegetation due to the partially contaminated topsoil. Considering that the motorway surface has already been renewed three times in some places during this period, it can be said that the GRS solution has so far proved to be much better than many had expected at the time.

Further information