Cogatec® Silo Roofs

Roof systems for gas-tight covering and storage of gas

Our Cogatec silo roofs for gas-tight covering of tanks are made of high-quality materials. Depending on the project requirements, you can choose between stainless steel and hardwood for the centre support. The fabric used is reinforced on the underside with PVC-coated, high-strength webbing. In addition, the integrated service opening enables easy maintenance work.

The tensioning of the silo roofs is done by means of a round tube and corrosion-resistant stainless steel ratchets. The round tube is inserted into a hollow seam.

The Cogatec product portfolio includes a roof with gas-tight lungs and a single-skin gas-tight silo roof. Both roof variants offer a choice between two clamping alternatives. With one, the gas-tight clamping is carried out on the inside of the container wall, with the other version, the clamping is carried out on the tank crown. This means that with the latter type of clamping, the roof can be opened at any time, even when the container is full.

Product variants

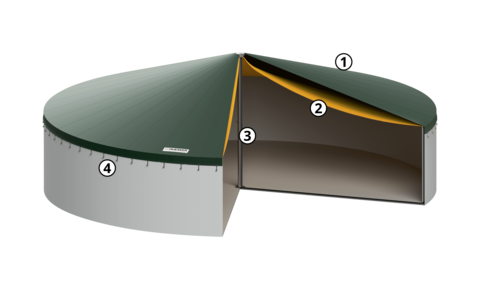

Silo Cover with Gas-Tight Lung

The silo cover with integrated gas-tight lung stores any kind of gases extracted from organic substrates. The roof system consists of two membranes: The painted outer membrane protects against weather influences such as snow, rain as well as storms and reduces the tarpaulin's susceptibility to dirt. The gas-tight inner membrane, also called the lung, traps the gas that is produced. Its gas-tight stainless steel A-connection is located at the centre support. Through the lung, the roof system is clamped gas-tight to the inside of the tank or onto the tank crown. Thanks to the use of high-quality stainless steel components, corrosion is effectively minimised.

Construction

| (1) Outer membrane (2) Inner membrane / lung | (3) Centre column (4) Tensioning with ratchets |

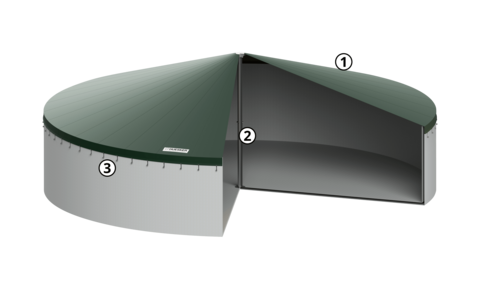

Silo Cover Gas-Tight

The gas-tight silo cover is a gas-tight standard roof construction and serves as a cover for fermenters and secondary fermenters. It is primarily suitable for storing gases that are produced and for significantly reducing emissions. For gas-tight clamping to the tank wall, there is a welded, extended PVC-coated polyester fabric on the inside of the cover. This is attached either to the tank crown or to the inner wall of the tank.

Construction

| (1) Outer membrane | (2) Centre column | (3) Tensioning with ratchets |

Technical information

PVC-coated fabric, fabric-reinforced, outside lacquered to reduce susceptibility to dirt

High tear resistance, low gas permeability, high UV stability

In combination with our overpressure and underpressure protection, a safe and gas-tight cover

Tensioning with stainless steel ratchets and high-strength webbing straps

Incl. gas-tight service openings available in various dimensions

Standard for use up to an opening pressure of +4.5 mbar and a negative pressure of -0.5 mbar