Groynes and Breakwaters

Sustainable Coastal and Bank Protection

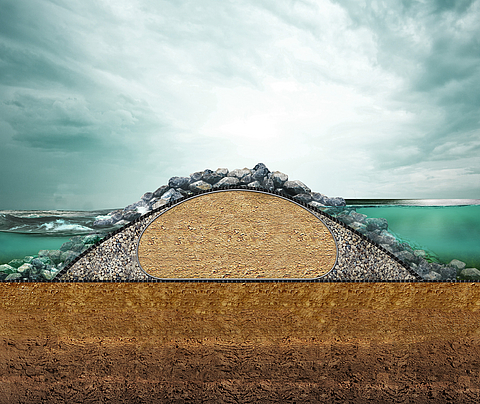

Conventional stone fill structures generally comprise a core, several filter layers and a top layer. Industrially manufactured geosynthetics and tailored system solutions incorporating custom-fabricated units allow the optimisation of structural geometries and cross-sections. Furthermore, the use of locally sourced materials such as sand vastly reduces the need for cost-intensive material shipments, e.g. of armour stone. The straightforward installation process and the use of geosynthetics of certified quality help to minimise risks and avoid the irregularities typical of mineral filter layers. Moreover, filter-stable installation of the core containment system prevents any erosion of the core material.

Scopes and Benefits of our geosynthetic building materials

Reinforcement/filter layer at base

Straightforward underwater installation compared to standard solutions

Evening out of settlement

Simultaneous filtration and separation function

Products: Stabilenka, Fortrac, Stabilenka Xtreme, HaTe Nonwovens, Sinking Mattresses, Tektoseal Sand

Use of geotextile containment systems

Rapid installation of barrier, even under water

Economical use of locally sourced materials (e.g. sand)

Products: SoilTain Coastal Protection Tubes, SoilTain Sandbags, SoilTain Dewatering Tubes

Constant filter layer thickness

High robustness

Reduced revetment construction thickness

Products: HaTe Nonwovens, Tektoseal Sand, Basetrac Woven

Permeable or impermeable geotextile concrete mattress layer

Filter-stable construction with smaller thickness

Rapid installation, even under water

Retrofitting feasible without any significant intervention in existing structure

Products: Incomat, SoilTain Sandbags, HaTe Nonwovens