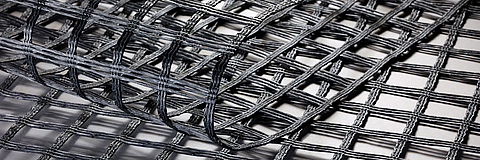

Fortrac® Geogrids

Highly resilient, flexible geogrid with a proven track record in soil reinforcement.

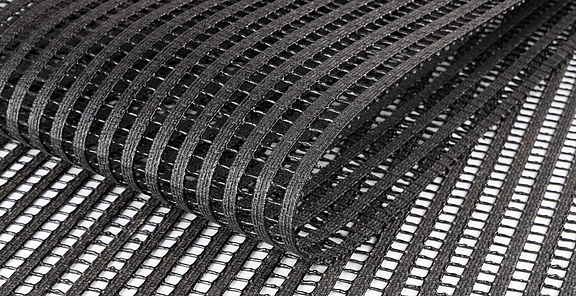

The flexible, high-strength Fortrac geogrid boasts a 30-year-plus track record in soil reinforcement applications. The geogrids are made from high-modulus, low-creep synthetic materials enclosed in a protective polymer coating. Moreover, they are manufactured in such a way as to guarantee high stability at the intersections. High-modulus polyester (PET) has been the standard raw material for our geosynthetics for over 30 years. In some cases, special requirements have prompted the use of advanced polymers, e.g. polyvinyl alcohol (PVA) and aramid. While aramid guarantees exceptionally high axial stiffness, PVA offers high axial stiffness in conjunction with extra-high resistance to chemicals - specifically, alkaline substances - in the soil.

Features

High tensile strength in conjunction with low strain

High specific strength

Excellent long-term behaviour due to low creep tendency

Easy installation due to low weight per unit area and flexible adaptable structure

Very wide range of strengths both uniaxial and biaxial

Project-related raw material selection possible

High available strength up to 3,000 kN/m

High long-term resistance even under demanding environmental conditions

Good interlocking effect due to optimum coordination between the width of the geogrid and the maximum grain size of the soil

Characterised by large and flexible roll dimensions that reduce material requirements due to overlaps and waste

Why choose Fortrac?

Fortrac geogrids can be manufactured from alternative raw materials where these better meet project requirements. The product's high flexibility allows easy handling and problem-free installation. Roll widths of 5 m promote the efficient and sustainable use of raw materials by minimising losses due to overlapping.

Fortrac® is a registered trademark of HUESKER Synthetic GmbH.

Our Fortrac product family

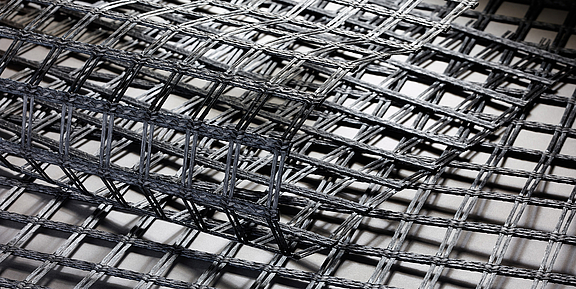

Fortrac T

Fortrac T soil reinforcement grid is made of high modulus, low

creep polyester yarns with a polymeric protective coating. Fortrac T has been the standard in geosynthetic raw materials for more than 30 years.

Benefits

- Low creep tendency

- Elongation at nominal strength: ≤ 10 %.

- Reduction in excavation and construction costs

- No loss of strength at the crossing points

- High interaction flexibility

- Very good adaptability

- Environmental Product Declaration (EPD) for the assessment of the sustainable use of resources and the impact of construction works on the environment

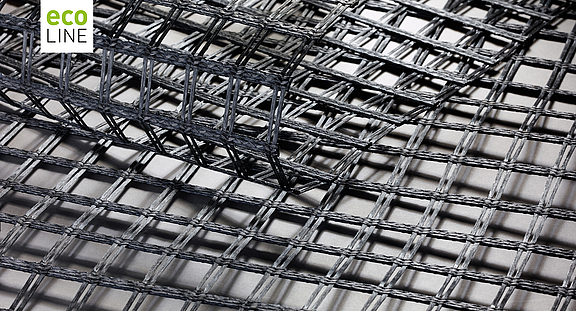

Fortrac T eco

The Fortrac T eco ground reinforcement mesh is made from high modulus polyester yarns produced from 100% recycled PET bottles. The sustainable ecoLine product variant has been proven to have the same performance and properties as the classic Fortrac T product made from original fibres. Thanks to the state-of-the-art production process, the PET recycled yarn achieves original fibre quality. With this product variant, we offer you a sustainable solution for the reinforcement of soil constructions using the highest quality German-made geotextile.

Benefits

- Sustainability and durability perfectly combined

- Extending the service life of traffic surfaces

- Particularly resistant to permanent dynamic traffic loads

- Interaction flexibility for best ground interlocking

- High tensile strength up to 1,600 kN/m

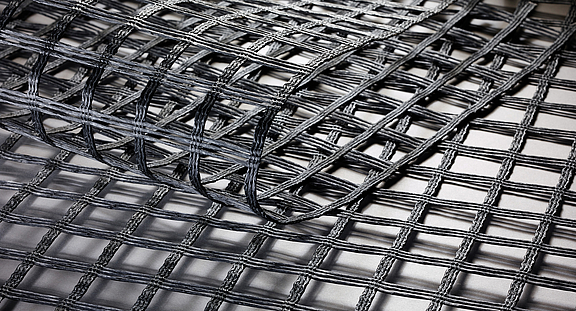

Fortrac MDT

The Fortrac MDT soil reinforcement grid consists of high-modulus alkali-resistant polyvinyl alcohol (PVA) yarns with a low creep tendency and a polymeric protective coating. The raw material used makes them particularly economical to install, as local soils with external pH values can also be used. Even soils with hydraulic binders such as cement or lime can be used without any problems thanks to Fortrac MDT.

Benefits

- Very low creep tendency

- Elongation at nominal strength: ≤ 6 %

- High extensional stiffness combined with high resistance

- Resistant in alkaline and acidic environments

- Reduction of excavation and construction costs

- No loss of strength at the crossing points

- High interaction flexibility

- Very good adaptability

- Environmental Product Declaration (EPD) for the assessment of the sustainable use of resources and the impact of construction works on the environment

Fortrac A

The Fortrac A ground reinforcement mesh consists of extremely high-strength and high-modulus aramid yarns with a low creep tendency and a polymeric protective coating. The raw material used makes it particularly suitable for use as sinkhole bridging.

Benefits

- Extremely high extensional stiffness combined with high resistance

- Tensile strengths up to 3,000 kN/m

- Widely used in demanding structures with high requirements on permissible deformations

- No loss of strength at crossing points

- High interaction flexibility

- Very good adaptability

Interaction flexibility

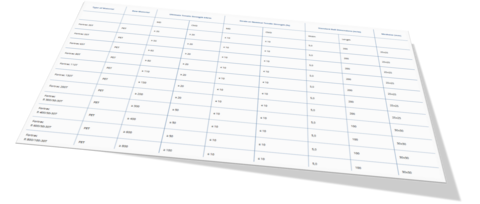

| Type of Material | Raw Material | Ultimate Tensile Strength kN/m | Strain at Nominal Tensile Strength (%) | Standard Roll Dimensions (m) | Meshsize (mm) | |||

|---|---|---|---|---|---|---|---|---|

| MD | CMD | MD | CMD | Width | Length | |||

| Fortrac 35T | PET | ≥ 35 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac 55T | PET | ≥ 55 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac 65T | PET | ≥ 65 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac 80T | PET | ≥ 80 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac 110T | PET | ≥ 110 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac 150T | PET | ≥ 150 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac 200T | PET | ≥ 200 | ≥ 20 | ≤ 10 | ≤ 10 | 5,0 | 200 | 25x25 |

| Fortrac R 300/50-30T | PET | ≥ 300 | ≥ 50 | ≤ 10 | ≤ 10 | 5,0 | 100 | 30x30 |

| Fortrac R 400/50-30T | PET | ≥ 400 | ≥ 50 | ≤ 10 | ≤ 10 | 5,0 | 100 | 30x30 |

| Fortrac R 600/50-30T | PET | ≥ 600 | ≥ 50 | ≤ 10 | ≤ 10 | 5,0 | 100 | 30x30 |

| Fortrac R 800/100-30T | PET | ≥ 800 | ≥ 100 | ≤ 10 | ≤ 10 | 5,0 | 100 | 30x30 |

| Type of Material | Raw Material | Ultimate Tensile Strength kN/m | Strain at Nominal Tensile Strength (%) | Standard Roll Dimensions (m) | Meshsize (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| MD | CMD | MD | CMD | MD | CMD | Width | Length | ||

| Fortrac 35 MDT | PVA | PP | ≥ 35 | ≥ 25 | ≤ 6 | ≤ 20 | 5,0 | 200 | 25x25 |

| Fortrac 55 MDT | PVA | PP | ≥ 55 | ≥ 25 | ≤ 6 | ≤ 20 | 5,0 | 200 | 25x25 |

| Fortrac 80 MDT | PVA | PP | ≥ 80 | ≥ 25 | ≤ 6 | ≤ 20 | 5,0 | 200 | 25x25 |

| Fortrac 110 MDT | PVA | PP | ≥ 110 | ≥ 25 | ≤ 6 | ≤ 20 | 5,0 | 200 | 25x25 |

| Fortrac 150 MDT | PVA | PP | ≥ 150 | ≥ 25 | ≤ 6 | ≤ 20 | 5,0 | 200 | 25x25 |

| Fortrac 200 MDT | PVA | PP | ≥ 200 | ≥ 25 | ≤ 6 | ≤ 20 | 5,0 | 200 | 25x25 |

| Fortrac R 300/50-30 MDT | PVA | PP | ≥ 300 | ≥ 50 | ≤ 6 | ≤ 20 | 5,0 | 100 | 30x30 |

| Fortrac R 400/50-30 MDT | PVA | PP | ≥ 400 | ≥ 50 | ≤ 6 | ≤ 20 | 5,0 | 100 | 30x30 |