Discover our base application world!

Permanent Traffic Areas

Base courses for public roads, car parks and industrial or logistics facilities with a bound surface course are required to offer high deformation resistance for a long service period.

The following geosynthetic solutions are recommended for the subgrade bearing capacities indicated below:

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

- < 10 MN/m²

- 10-30 MN/m²

- 30-35 MN/m²

- > 35 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

Railways

In the railway engineering segment, base courses for both new-build and refurbishment projects are governed by special regulations. The track bed construction must ensure the deformation-free accommodation and transmission of high dynamic loads over a long service period.

In addition to the particular geosynthetic solutions for the indicated subgrade bearing capacities, we also recommend expert design counselling by our engineers:

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

- < 10 MN/m²

- >10 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

Temporary Roads

These applications cover site haul roads and access routes of unbound construction. These are built either for intensive use over a limited period (< 2 years) with subsequent removal (haul roads) or for a longer period of only sporadic use (e.g. access routes to wind turbines or little-trafficked forestry roads).

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

- < 10 MN/m²

- 10-20 MN/m²

- 20-35 MN/m²

- > 35 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

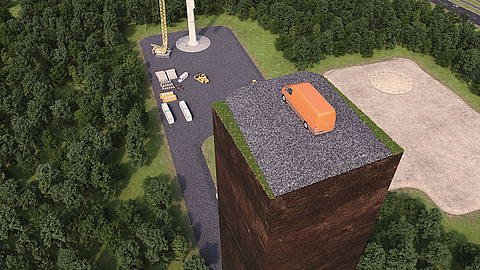

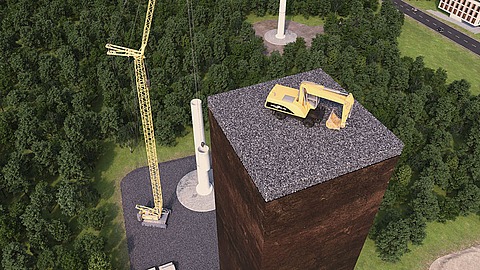

Working Platforms

Foundation levels and, in particular, crane bases (e.g. for wind turbines) are often required to safely accommodate high short-term loads. Here, the base course must offer high resistance to deformation to meet the high risks posed by structural failure and collapse.

In addition to the particular geosynthetic solutions for the indicated subgrade bearing capacities, we also recommend expert design counselling by our engineers:

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

- < 10 MN/m²

- >10 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

Permanent Traffic Areas

Base courses for public roads, car parks and industrial or logistics facilities with a bound surface course are required to offer high deformation resistance for a long service period.

The following geosynthetic solutions are recommended for the subgrade bearing capacities indicated below:

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

- < 10 MN/m²

- 10-30 MN/m²

- 30-35 MN/m²

- > 35 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

Railways

In the railway engineering segment, base courses for both new-build and refurbishment projects are governed by special regulations. The track bed construction must ensure the deformation-free accommodation and transmission of high dynamic loads over a long service period.

In addition to the particular geosynthetic solutions for the indicated subgrade bearing capacities, we also recommend expert design counselling by our engineers:

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

- < 10 MN/m²

- >10 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

Temporary Roads

These applications cover site haul roads and access routes of unbound construction. These are built either for intensive use over a limited period (< 2 years) with subsequent removal (haul roads) or for a longer period of only sporadic use (e.g. access routes to wind turbines or little-trafficked forestry roads).

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

- < 10 MN/m²

- 10-20 MN/m²

- 20-35 MN/m²

- > 35 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

One-layer base course construction

PP wovens offer an appropriate solution for these subgrade conditions in that they provide adequate reinforcement while also performing a separation and filtration function. Geogrids, which offer even better interaction flexibility, can of course be selected as an alternative.

In most cases, no reinforcement is needed here due to the adequate bearing capacity of the subgrade. Nonwovens are the best option where a separation and filtration function appears useful.

Working Platforms

Foundation levels and, in particular, crane bases (e.g. for wind turbines) are often required to safely accommodate high short-term loads. Here, the base course must offer high resistance to deformation to meet the high risks posed by structural failure and collapse.

In addition to the particular geosynthetic solutions for the indicated subgrade bearing capacities, we also recommend expert design counselling by our engineers:

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.

- < 10 MN/m²

- >10 MN/m²

Two-layer base course construction

- If crushed stone/aggregate or coarse gravel is to be placed on the subgrade as the base course material, we recommend the incorporation of a composite product as the first layer on the subgrade.

- If sand is to be placed on the subgrade as the base course material, we recommend the use of a PP woven. Here, the sand is packed into the woven to form a cushion-like assembly.

- Crushed stone is then placed as the second layer on top of the first layer. As a base for this, we always recommend a geogrid due to the good interlock and interaction flexibility.

To meet special requirements involving very high tensile strengths, we recommend Stabilenka or Stabilenka Xtreme wovens and Fortrac geogrids.

Please feel free to ask our experienced engineers for support in the design of your project.

One-layer base course construction

Composites or geogrids with a reinforcing effect are recommended for these applications due to the low bearing capacity of the subgrade.

Composites are useful where the geosynthetic product needs to offer a separation and filtration function in addition to its reinforcing action, e.g. with cohesive soils. Geogrids are used where only a reinforcing function is required, e.g. with non-cohesive soils.

Please feel free to ask our experienced engineers for support in the design of your project.