Basetrac®Plate enables sustainable and efficient road construction solutions

HUESKER Synthetic GmbH presents Basetrac® Plate, a new, recyclable load distribution plate that combines maximum load-bearing capacity with minimum weight – for safe trafficability and soil protection in temporary construction projects.

With the new Basetrac Plate, the HUESKER Group, based in Gescher, Westphalia, is expanding its portfolio with an innovative load distribution plate that guarantees maximum load-bearing capacity with minimum weight. Developed for temporary access roads, cable routes or storage areas, it offers a sustainable solution for unrestricted trafficability and reliable soil protection – even under extreme operating conditions. Basetrac Plate is fully recyclable, up to 80 per cent lighter than conventional plates and can be laid quickly and cleanly. It thus meets the requirements of modern construction projects in terms of sustainability, cost-effectiveness and efficiency in equal measure. It can also be reused multiple times without additional maintenance.

"With Basetrac Plate, we offer our customers a load-bearing and resource-saving solution that perfectly combines handling, logistics and sustainability."

Sven Schröer, CSO HUESKER Synthetic GmbH

Innovation made in Germany

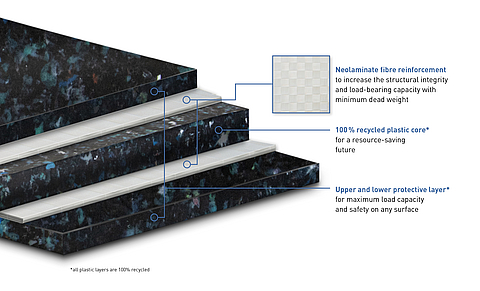

Basetrac Plate is based on a combination of HUESKER's Neolaminate® and 100% recycled plastic. The optimised fibre orientation of the Neolaminate ensures maximum force absorption with minimum weight. With a plate thickness of only 23 mm, Basetrac Plate is significantly slimmer than conventional load distribution plates and is also completely reusable. Even under heavy loads, it ensures uniform trafficability. Thanks to efficient logistics, a single truckload can cover an area of 1,043 m² – up to seven times more than with conventional solutions. "Basetrac Plate combines low weight, high load-bearing capacity and full recyclability – a win for efficiency and sustainability on every construction site," summarises Oliver Detert, Head of Engineering Department Technology at HUESKER Synthetic GmbH.

Basetrac Plate - Advantages at a glance

- Up to 80% lighter than conventional plates

- 100 % recycled core, fully recyclable

- Panel thickness only 23 mm – space-saving and easy to handle

- Quick, clean installation and easy dismantling

- Coverage of up to 1,043 m² with just one lorry load

"With Basetrac Plate, we have developed a solution that makes everyday construction site work noticeably easier. Compared to conventional road slabs, it is significantly easier to transport, quicker to lay and, at the same time, extremely resilient."

Oliver Detert, Head of Engineering Department, HUESKER Synthetic GmbH

Comprehensive base course concept

The Basetrac product family offers high-performance geosynthetic solutions for a wide range of applications in base course reinforcement. Whether for permanent traffic areas, temporary access roads, work platforms or railway construction, Basetrac products provide the right combination of reinforcement, separation, filtration and load distribution. In addition to the new Basetrac Plate, the portfolio includes woven geogrids, composites made of geogrids and nonwovens, geotextile nonwovens and tape fabrics.

The Basetrac product portfolio

| Function | Special Features | Typical Application | |

| Basetrac Plate | Load distribution, floor protection | Neolaminate core, 100% recycled, 23 mm thick | Cable trays, wind farms, storage areas |

Basetrac Grid | Reinforcement | Woven geogrid, PP/PET/PVA | Road construction, logistics and industrial areas |

| Basetrac Duo-C | Reinforcement, separation, filtration | Composite geogrid + nonwoven fabric | Permanent traffic areas, logistics and industrial areas |

| Basetrac Nonwoven | Separating, filtering | Geotextile nonwoven fabric, PP/mixed fibre | Base layer material separation, soil protection |

| Basetrac Woven | Reinforcing, separating, filtering | Tape fabric, PP | Temporary roads, construction sites |

Designing environmentally conscious projects

With Basetrac Plate, HUESKER is setting new standards in temporary surface reinforcement – technically efficient, economical to use and sustainable in production.

Compare our solutions online and find exactly the right one for your project – for example, with the https://www.huesker.co.uk/geosynthetics/services/software/basecalculator/.

For further information, please visit https://www.huesker.co.uk/or contact us for a personalised consultation.