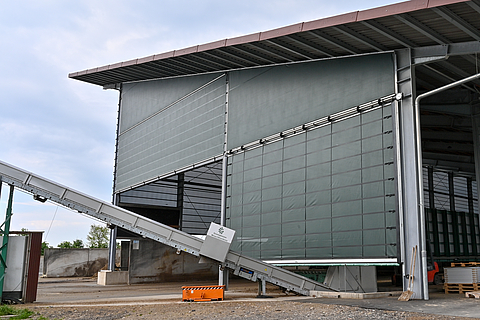

Textile weather protection for warehouse with Tectura folding fronts and tensioning variants

Project information

Construction project

New construction of a storage hall for manure and wood chipsCustomer

Bioenergie Guntrup Verwaltungs GmbHConstruction

Möhlenkamp – Textile SystemlösungenLocation

Greven , DEPlaning

Möhlenkamp – Textile SystemlösungenConstruction time

April 2024Products used

Project details

Situation

Bioenergie Guntrup operates plants in Greven for the production of renewable energy and focusses on the sustainable use of organic waste materials. For the new construction of a 33 m × 80 m storage hall for manure and wood chips, the requirement was to reliably protect the stored goods from the weather. At the same time, the building environment had to be permeable to daylight and ensure maximum air circulation to prevent the build-up of moisture and odours. Another important aspect was the conveyor belt area, where the option to open and close the area was a requirement.

Solution

In close consultation with the engineers at HUESKER Synthetic GmbH, the hall was equipped with textile tensioning variants. A net with 92 % wind braking capabilities (type 60/60-1) was used. It reliably protects the hall from wind and precipitation while ensuring good air permeability and daylight. A Tectura folding front was also installed for flexible use in the conveyor belt area. This allows the halls to be opened and closed quickly and easily so that conveying processes can run unhindered. The combination of fixed clamping variants and a movable door system ensures maximum functionality while providing a high level of protection for the stored goods.

Advantages

The implemented solution meets the operator's individual requirements for the new warehouse and combines several advantages. The mesh used reliably protects manure and wood chips from rain and draughts without hindering the necessary natural air exchange. This keeps the stored goods dry and prevents the formation of moisture and mould. The high natural light input also reduces the need for artificial lighting. Meanwhile, the Tectura folding front enables flexible operation in the conveyor belt area and ensures smooth integration into operational processes. Thanks to the lightweight, corrosion-resistant and durable materials, the solution offers sustainable and economical protection for the new warehouse.