GRS for one of Britain’s oldest industrial sites

Project information

Construction project

Kirkstall ForgeCustomer

Commercial Estates GroupConstruction

I&H BrownLocation

Leeds , UKPlaning

WYG Ltd.Construction time

October 2014 to August 2015Products used

Project details

Project description

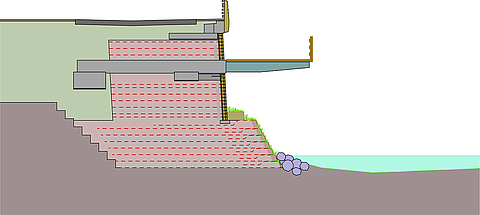

Commercial Estates Group is carrying out the first phase of a £400M project to regenerate Kirkstall Forge, one of Britain’s longest continually used industrial sites, which dates back to the 12th Century. The first kirkstall Forge was built in the 1580s and iron and steel were produced on the site until 2002, when the most recent facility was closed and manufacture moved overseas. When complete, the 23ha site will have a new community of 1,050 homes, 300,000 sq ft of commercial offices, along with cafes, restaurants, retail and leisure facilities. It will be served by a new railway station linking it in minutes with Leeds city centre. Construction of the first phase began in October 2014, with main contractor I&H Brown carrying out earthworks and constructing initial infrastructure. Construction of the first 110,000 sq ft of commercial office space and 240 apartments, plus the new railway station, were built under separate contracts. Civil engineering and environmental consultancy for this phase is being provided by Leeds City Council and WYG. A key element of the project was the construction of a road between the A65 Abbey Road running along the site’s northern boundary and the new station to the south, which required crossing the River Aire bisecting the site. The site is in the bottom of the river valley and the A65 is about 15m higher than the river, so ground levels had to be raised between the ‘Stitch Bridge’ and the main road to create a suitable road gradient. Additionally, the underside of the bridge deck had to be 600mm above the 1 in 100 year flood level, which meant raising the height of the northern river bank and reinforcing the southern one, to accommodate the 30m long, 18m wide bridge span.

Solution

Reinforced soil walls were chosen to support the new crossing, after a sheet pile solution was rejected at the design stage as it was considered to be too time-consuming and expensive to install.

Design was carried out by I&H Brown’s specialist installer Thomas Ben and its reinforced soil consultant PaSCoE. The plan was to replace 210m of the northern river bank and 125m of the southern bank with new slopes constructed from imported and site won granular fill, reinforced with multiple layers of HUESKER’s uni-axial polyester Fortrac geogrids.

The northern bank was raised a further 5m by placing more layers of granular fill reinforced with Fortrac geogrids on top of the slope, faced with an Allan Block segmental block retaining wall. The bridge was founded on concrete bank seats built directly on the new reinforced soil structures. One of the challenges was to satisfy Leeds City Council’s bridges and structures team that building a bridge with a 120 year design life on a reinforced soil slope would be acceptable. HUESKER presented similar projects from across Europe to demonstrate the solution’s success and, along with Allan Block, introduced a ‘positive connection’ between the geogrid and the wall, giving added strength to the structure.

Previously, the connection would have been provided by the friction between the blocks, but the new approach involved wrapping the geogrid around positive connection bars sitting in recesses on the top of the blocks, giving higher connection strengths and allowing more flexibility in the geogrid vertical spacing and layout.

The 37°-60° reinforced soil slopes included up to 16 layers of Fortrac geogrid, placed on 400mm thick layers of compacted granular fill. Two types of Fortrac T were used, with ultimate tensile strengths of 55kN/m and 80kN/m, anchored up to 12m into the slopes, depending on their height, which varied along the river to a maximum of 6.2m. The bridge’s bank seats sit on nine layers of Fortrac with ultimate tensile strength of 110kN/m, with anchor lengths of 10m, behind the block facing.

The slope face was formed by wrapping the geogrid around and back on itself, behind which topsoil and a green mesh was placed, creating a natural looking river bank. The near-vertical Allan Block wall used combinations of Fortrac 80T and 110T geogrid, laid at 200mm and 400mm centres, with anchor lengths of 7m. The walls were formed of concrete blocks sitting on a levelling strip of C32/40 concrete and are founded directly on the reinforced slope. A challenging part of the project was the requirement for a cantilevered pedestrian platform to be founded directly in the reinforced soil along part of the north river wall. This is believed to be the first of its kind in the UK. The walkway is supported on a series of steel beams, partially encased in concrete, which pass through the reinforced soil block and are supported by a mass concrete foundation, to counterbalance the load on the platform. Ground conditions adjacent to at the river comprised up to 5m of made ground (mainly demolition material, plus ash and clinker from the forge), over alluvial sand and silt and river terrace gravels, with weak mudstones and siltstones at about 12m depth.

The new reinforced soil slopes are founded in the river terrace gravels so I&H Brown designed and installed temporary sheet pile walls to allow excavation in the dry.

Benefits

- Providing reinforced soil bridge foundations with 120-year design life

- Ability of the reinforced soil design to incorporate cantilevered walkway

- More economical and faster than a traditional sheet pile solution

- Sustainability through the use of site-won materials and Fortrac geogrids.

Further information