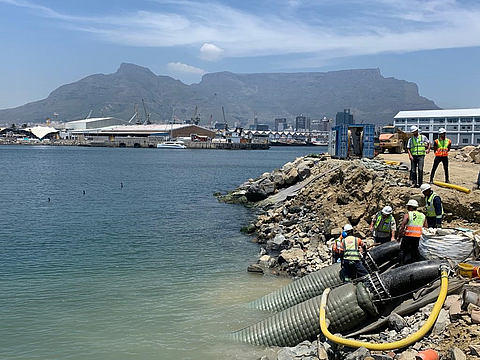

Pipe protection installation under water - Cape Town

Project information

Construction project

Pipe protection inlet pipes V&A Waterfront desalination plantCustomer

Victoria & Alfred Waterfront HoldingsConstruction

Guerrini Marine ConstructionLocation

Cape Town , ZAFPlaning

WSP Consulting Engineers Cape TownConstruction time

October to December 2019Products used

Project details

Situation

In 2017 and 2018, there was an acute water shortage in the Western Cape province of South Africa. Even the nearby dams were unable to meet the water needs of the Western Cape region. One of the reasons for the shortage was the large influx of foreign refugees into the Western Cape housing estates, which meant that the existing supply infrastructure could no longer meet demand. The City of Cape Town (CoCT) then decided to build several desalination plants to produce fresh water using the reverse osmosis process. Eight sites were originally planned, but today only three desalination plants are in operation. One of these is the V&A Waterfront desalination plant in Cape Town harbour. During construction, flexible HDPE pipelines with different geometries were laid into the water on an embankment. Due to the exposed location on one of the harbour's busiest waterways, the pipes also needed to be protected against damage during installation and from shipping traffic.

Solution

Based on existing, positive experience with Incomat products, WSP Consulting Engineers Cape Town, who were the planning consultants involved in the construction project, recommended protecting the pipes with the help of HUESKER’s Incomat product portfolio. The choice fell on the Incomat Pipe Cover (IPC) system (in jacket format) used especially for pipe protection applications. After a detailed analysis of the long-term durability requirements of the project, the HUESKER hydraulic engineering team recommended the use of HUESKER Incomat IPC with an average thickness of 200 mm, followed by a layer of filter rock (3-15 kg) as a protective underlay on the pipelines before the revetment (700-2000 kg) was installed on top. The implemented solution provides efficient protection of the pipelines against damage, which was to be expected mainly during the construction phase, but can also be caused by the impact of large watercraft.

Advantages

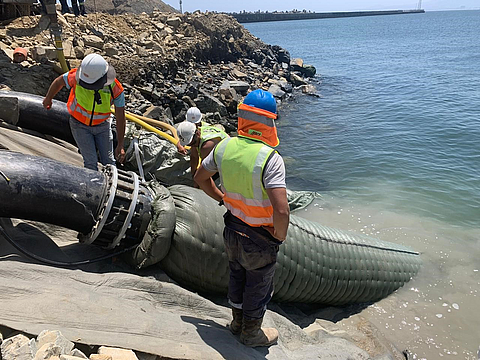

Incomat Pipeline Cover from HUESKER is a special, ring-shaped pipeline protection consisting of a geotextile formwork mattress with factory-fitted industrial zip fasteners. Its use eliminates the need for time-consuming formwork on site, saving time and money. In addition, the durable, high-strength polymer fabric can be quickly filled with fluid concrete, which also speeds up construction progress on site.

Another advantage of the Incomat system is the unique ability to fill the mattress safely and efficiently underwater. Only a small team was required for the underwater installation. One diver supervised the work on the surface while two other divers placed and sealed the Incomat Pipeline Cover underwater. This simple installation method was possible even in the very poor visibility conditions that prevailed in the commercial harbour during operating hours.

As part of its holistic approach to providing efficient solutions, HUESKER Synthetic assisted the technical project team from WSP Consulting Engineers Cape Town with the detailed design from the outset. In the early stages of the project, HUESKER Synthetic trained the contractor's staff and local engineers to ensure efficient installation for enhanced product performance. HUESKER's hydraulic engineering and coastal rehabilitation experts also provided advice and practical recommendations up until the project was fully completed.

Further information