Unique and sustainable waterproofing solutions with NaBento® and Tektoseal®

Simple, economical and safe sealing for almost any construction project

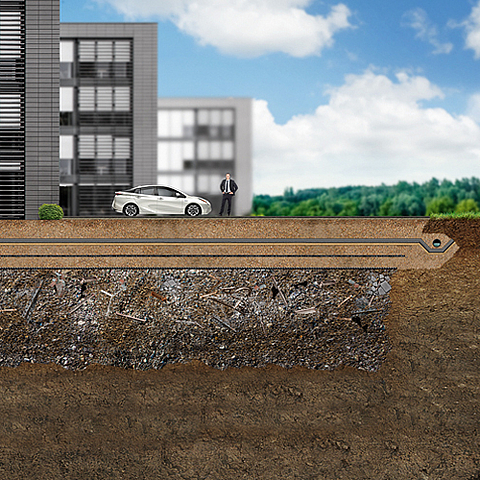

Geosynthetic clay liners (GTD), also known as geosynthetic bentonite mats (GBR-C), have offered a proven and innovative solution for reliable sealing in sensitive areas of application for decades. Whether in landfill construction, remediation of contaminated sites, groundwater protection, hydraulic engineering or traffic route construction, GTD systems provide an ecologically and economically convincing alternative to conventional mineral waterproofing.

The products of the NaBento and Tektoseal Clay brands stand for maximum technical performance, permanent impermeability and long-term environmental compatibility. Their recipe for success: an intelligent combination of geotextile carrier layers and a central bentonite layer, which is characterized by its high proportion of montmorillonite - a clay mineral with exceptional swelling properties. This combination ensures extremely low water permeability and adapts flexibly to different installation and environmental conditions.

With the latest product development in the NaBento range, we are underlining our commitment to quality and innovation. In addition to optimizing the sealing properties, the main focus is on sustainability: a newly developed, sand-rough special composite material replaces the previous cover and base layers and ensures improved performance thanks to its high external shear strength, especially on slopes and dynamically loaded installation surfaces.

Thanks to the option of using bentonite in powder or granular form, depending on the application, our GTD solutions are modular and versatile. In this way, planners, construction companies and operators benefit from maximum efficiency during installation and operation while minimizing the use of resources.

Find out how our geosynthetic clay liners can support your project safely, sustainably and economically. Our team will be happy to assist you personally!

Individual product solutions for your requirements

NaBento® IR-C

Maximum security and performance

NaBento IR-C is a sustainable high-performance geomembrane designed for versatile applications in construction and environmental engineering. Based on decades of experience in the development of geosynthetic clay liners (GBR-C), NaBento IR-C offers a new waterproofing solution that sets new standards both technically and ecologically.

The innovative structure of geotextile composites, optionally integrated root protection and high-quality calcium bentonite guarantees excellent sealing and installation properties. NaBento IR-C is the only GTD on the market that is not affected by natural cation exchange, a decisive advantage for lasting stability and chemical resistance. This makes it the ideal choice for durable, resilient waterproofing systems, even under demanding conditions.

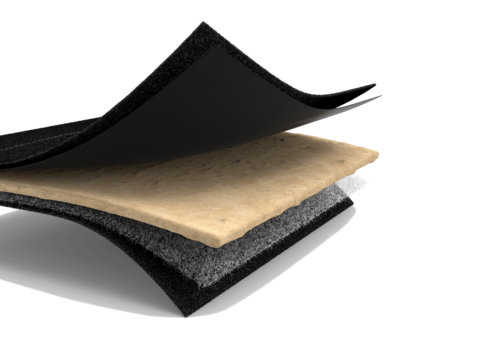

Layer structure NaBento IR-C

- Special sand-treated composite as top layer for maximum external shear strength

- Root protection for effective protection against root penetration

- Up to 11 kg/m² calcium bentonite for maximum impermeability

- Support fleece for high erosion resistance

- Special sand-colored composite as a base layer for maximum external shear strength

Tektoseal® Clay NA

The classic with added value

Tektoseal Clay NA represents the modern evolution of industrially manufactured sealing systems. Based on sound findings from research and practice, a high-performance sealing product has been developed that combines functionality, safety and ease of application at the highest level.

The result is an extremely swellable and sinkable clay liner, consisting of a finely tuned multi-component system of robust geosynthetics and high-quality sodium bentonite granulate. The individual layers are bonded to each other over the entire surface using specialized precision needling. This makes Tektoseal Clay a homogeneous, mechanically resilient geomembrane of consistently high quality.

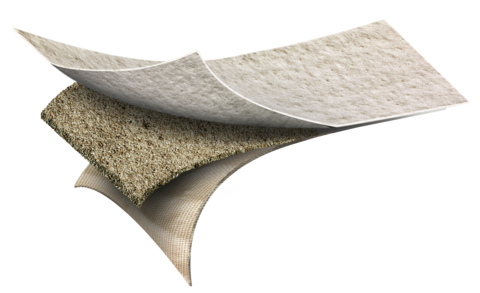

Layer structure Tektoseal Clay NA

- Non-woven top layer for high flexibility and protection

- Up to 7 kg/m² sodium bentonite for optimum impermeability and sag resistance

- High tensile strength fabric as backing material for maximum load-bearing capacity

Flexible modular system for individual product configuration

Tailor-made clay liner for every requirement

Needled

- High internal shear strength

- Erosion-proof fixation of the bentonite

Stitched

- Very high tensile strength

- Bentonite weight of up to 11 kg/m2 possible

- High push-through resistance

Powder

- Extremely low permeability

- Fast sealing effect

Granules

- Sinkable

- Very good paving conditions (no dust formation, non-slip)

Sodium bentonite

- High swelling capacity

- High water absorption capacity

Calcium bentonite

- No loss of performance due to cation exchange

- Low shrinkage cracking

- Resistant to weather conditions such as frost and drought

Sandrauer special composite material

- Unique technology for very high external shear strength

- Improved interaction with contact surfaces such as plastic sealing sheets, nonwovens or drainage sheets

Protection against root penetration

- Effective protection against root penetration

- Internal film for seamless overlaps during installation

- Reliable swelling in direct contact with concrete (increased alkalinity)

Aerofleece

- Internal fleece for high erosion resistance

- Additional stability and resistance

Edge scattering

- Ensures production of sealed overlap areas

- Reduced installation effort, as no manual application necessary

- No welding or other joining techniques required

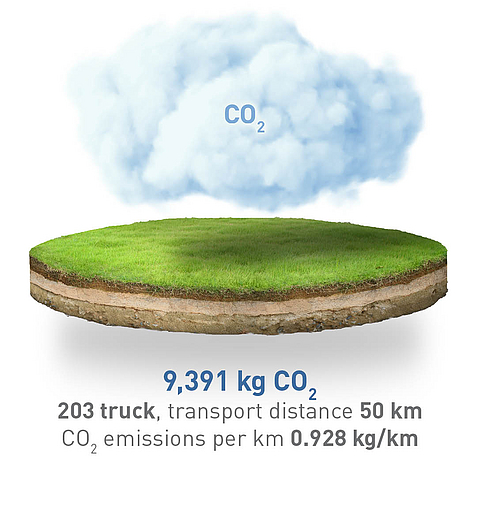

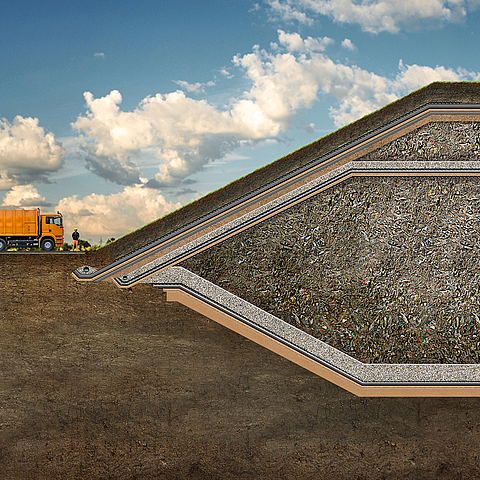

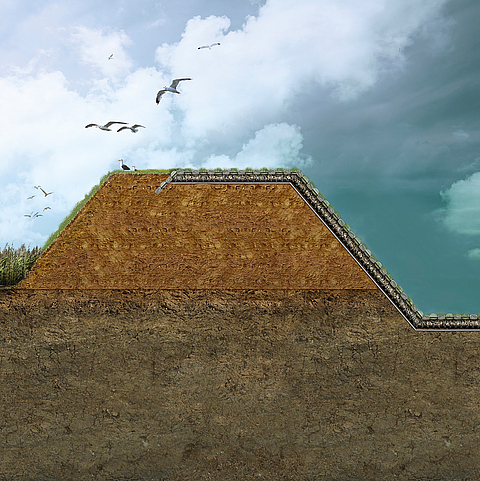

Reduction of tire abrasion and CO2 emissions through the use of GTB

Calculation example of a surface sealing of landfills

The material transport for a fictitious landfill sealing is compared. The construction project is considered once with a sealing made of geotextile bentonite mats and once with a sealing made of clay. A landfill area of 4,500 m² is assumed.

Sealing made from geotextile bentonite mats

Sealing made of conventional clay

Result: A comparison of the two solution concepts clearly shows that a landfill with geotextiles produces up to 96% less microplastics from tire abrasion under the parameters listed above than the expansion variant with a clay seal. In addition, the transportation of the clay mineral produces 94% more CO2. Added to this is the additional CO2 impact caused by the use of machinery during installation, which is significantly lower with the geosynthetic variant. Furthermore, the construction costs are generally lower when using a geotextile solution.

The modern solution for efficient surface sealing

Geosynthetic clay liners have long since established themselves as an efficient and practical alternative to traditional mineral waterproofing membranes. With their intelligent combination of materials and versatility, they offer technical and economic advantages that are increasingly in demand, especially in modern construction projects.

A key advantage is their low weight and volume. Compared to conventional waterproofing materials, this significantly reduces transportation costs and simplifies handling on the construction site. The prefabricated membranes can be laid quickly, easily and regardless of the weather. This not only saves time, but also increases installation safety.

When installed, GTBs impress with their excellent resistance to mechanical stresses. Even with dynamic loads, subsidence or dimensional changes, the sealing function is permanently retained. The result: a reliably effective seal, even under demanding environmental conditions.

With their combination of technical performance, ease of processing and economic efficiency, geosynthetic clay liners are now regarded as a pioneering solution in surface sealing - in infrastructure, hydraulic engineering and environmental technology alike.

- Surface sealing

- Improvement of geological barrier

- Road construction/railway construction in water protection areas

- Rainwater retention basins

- Storage ponds

- Landscaping

- Airfield construction

- Surface sealing

- Base sealing

- Dams and dikes

- Flowing and standing waters

- Drainage ditches