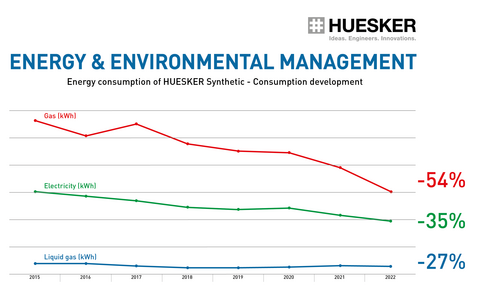

The topic of sustainability is on everyone's lips. Often, it remains lip service. This is not the case with HUESKER: We don't get tired and continue to push ourselves forward to save even more energy. In the meantime, the kilowatt hours saved are in the millions. And the path continues – until the CO2 footprint is balanced.