Do geogrids from HUESKER really generate less CO2 than conventional solutions? In a road construction project in Brazil, we proved it.

Do geogrids from HUESKER really generate less CO2 than conventional solutions? In a road construction project in Brazil, we proved it.

The customer wanted a high retaining wall with a 90° inclination. No problem: We realized this job with a reinforced earth body and a facing made of steel lattice elements. In this process, the body of the earth is reinforced by laying Fortrac geogrids and earth in layers. The facing, made of corrosion-protected grid elements, is then filled with natural stones. The economic advantages of this construction method are obvious:

But what about the environmental benefits? With often empty household coffers and the compulsion to save, this question unfortunately takes a back seat far too often. But our client wanted to know more. To our delight, he asked us to check whether our solution was actually more sustainable than the conventional concrete alternatives.

The Challenge: Comparing Environmental Impacts

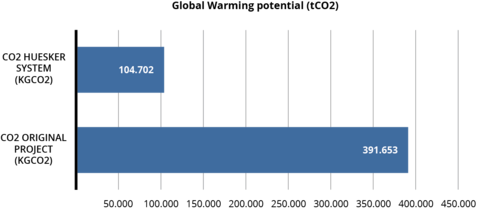

The creation of a concrete comparison within the framework of a meaningful CO2 balance was a major challenge. Our documentation had to be "watertight" in every respect in order to fully meet scientific standards. As a first step, we used the information on greenhouse gas emissions contained in the Environmental Product Declarations (EPDs) of HUESKER products. For comparison, we received EPDs of the products used for conventional solutions. Our analysis was completed with literature data on natural materials. We then calculated the amount of embodied carbon for each m² of wall area of the HUESKER system and performed the same calculation for the conventional alternatives. The results were impressive.

Geogrids have been proven to reduce the CO2 footprint

With HUESKER's construction and products, the CO2 footprint has been reduced by approximately 300,000 kg CO2 compared to the original project. That's the equivalent of a car journey 58 times around the globe! In our comparison, a large part of the greenhouse gases can be traced back to the energy-intensive production of the climate killer cement, which is responsible for 8% of global emissions. If the cement industry was a state, it would be the third-highest emitting nation in the world. Geogrids consume significantly less energy during production than concrete and at the same time conserve resources. Our CO2 balance makes it clear: It's worth comparing, because sustainability is measurable and much more than just a "nice accessory". An intelligent selection of materials and construction methods offers both economic and ecological advantages. The aim must be to ensure that comparative life cycle assessment is given greater consideration in public tenders - for a sustainable future and added value for the customer.

Our project is excellent

During the process, we were able to convince our clients with quality and environmental friendliness, which was also pleasantly reflected in our customer's sustainability report. In addition, we had the opportunity to score points at the national level with our "comparison project": as a participant in a competition promoted by the Brazilian Chamber of the Construction Industry to reward innovation and sustainability. We are delighted about the nomination and are proud of the 3rd place. A great success that encourages us to build even more on truly sustainable solutions.

Yours, Emilia